MOVE TO WIP

Move components to shop floor, and automatically adjust inventory.

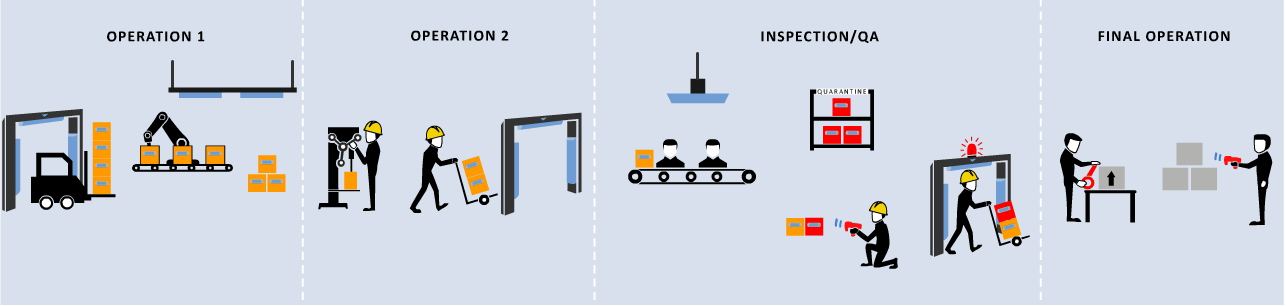

OPERATION 1

Reader on conveyor causes update to status, pedigree, and location of component.

OPERATION 2

Exit portal causes update to status, pedigree, and location.

PASS/FAIL

Update component status. Quarantine Failed components. Passed components continue.

FAILED ALERT

Portal BEEP…Failed items disallowed. Location updated for Passed components.

FINAL ASSEMBLY

Component ID rolled up under full assembly ID. Status and pedigree updated.

Track materials through the production process

Lean businesses are extremely vulnerable to shortfalls in materials availability. A missing component can bring an assembly line to a screeching halt, and production efficiency plummets. Every human touch point is an opportunity for error. And as materials, tooling, sub-assemblies, and containers interchange, there is increased risk of materials being mishandled or misplaced.

Work-in-process (WIP) tracking can eliminate errors and delays by providing much needed checks and visibility at the component and process level, as products pass down the production line. Strategically positioned check points can ensure that materials are kitted correctly, properly accounted for, and replenished at the right time. Exceptions such as steps being taken out of sequence can be trapped, and as products transition from raw materials to final assembly you can build their pedigree record – a vital audit trail for troubleshooting and support as well as regulatory compliance in some industries. This is the Smart Manufacturing revolution.

TraxWare for Work in Process

TraxWare for Work in Process enables manufacturers to automatically track materials, containers, sub-assemblies, personnel, and equipment at each step of the manufacturing process. By cutting out human touch points and adding process checks, TraxWare helps manufacturers control asset shrinkage, reduce production errors and delays, improve production quality and maximize overall equipment efficiency. TraxWare supports your Smart Manufacturing initiatives.

Unlike other WIP solutions, TraxWare’s modularity makes it extremely adaptable to unique processes. Why suffer the disruption and risk of reengineering familiar processes to fit the needs of an automation system? It should be the other way around! TraxWare for WIP delivers a fast return on investment because it deploys rapidly and fits into your business processes just as they are designed, with minimal need for process reengineering. The resulting process visibility and efficiency gains, leave your business poised for growth.

Key Features:

- Complete visibility over the process lifecycle between discrete points of measure

- Customized design to meet existing and future state workflow

- Faster, better informed exception handling

- Pedigree reports for compliance and warranty tracking

- Real-time visibility of inventory and production status at all levels

- Interface with existing MES, accounting and database system

- Seamless interfaces with existing MES, CRM, and ERP database systems

Use TraxWare for WIP to improve quality and maximize production efficiency, by eliminating human touch points and by tracking components from beginning to end through the production life-cycle.